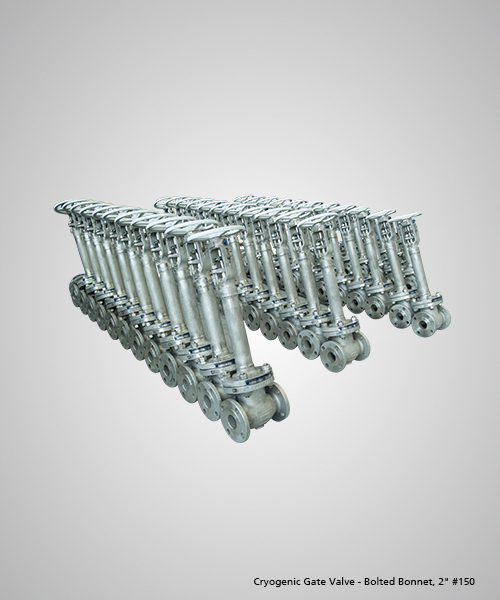

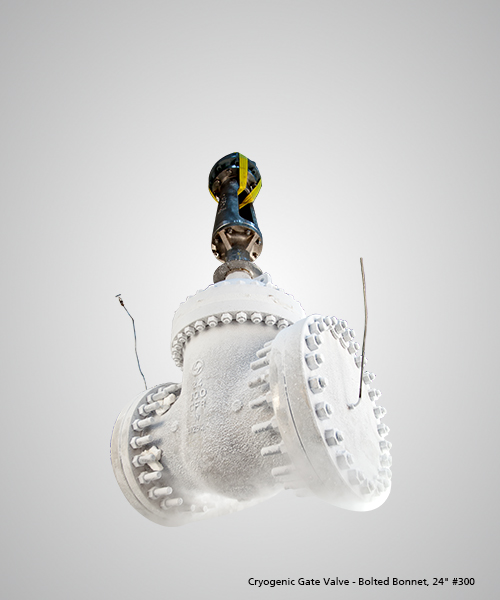

Cryogenic Valves

Cryogenic Gate, Globe & Check Valves

| Gate Valves: | Size: 2" to 54" (50 mm to 1350 mm) ASME Class: 150 to 2500 Design Standards: API 600, ASME B16.34, BS 6364, ISO 28921 |

| Globe Valves: | Size: 2" to 24" (50 mm to 600 mm) ASME Class: 150 to 600 Design Standards: API 623, BS 1873, ASME B16.34, BS 6364, ISO 28921 |

| Check Valves: | Size: 2" to 36" (50 mm to 900 mm) ASME Class: 150 to 2500 Design Standards: API 594, BS 1868, ASME B16.34, BS 6364, ISO 28921 |

Beyond Standards:

- Fugitive Emissions - Complies to ISO 15848-1: Endurance class CO2 and Tightness class BH

- Valves tested at -196 degree C as per BS 6364. In-house facility for valves up to 60”

- SIL3 Safety Integrity Level for Automated Valves

- Cryogenic valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors

- Optional tests - EN 12567 Annex A (Thermal Shock Test) and Annex B (Endurance Test)

Features that Add Value:

- Bonnet extension/ extension column keep packing rings away from cryogenic temperatures, and within its operating range

- Thermal stabilization treatment conducted on body and obturator to ensure dimensional stability and to avoid distortion during temperature cycles

- Cavity relief pressure arrangement to prevent thermal effect

- Seat and disc hardfaced to prevent seizing and galling

Versatile Solutions:

- Available in a wide grade of metallurgies for a range of low temperature applications.

- ValvTrac™ RFID tags for reliable digital traceability